For artists and collectors sponsored by Intercal...your mohair supplier and Johnna's Mohair Store

I have been using cotter pins for my bears but I am trying to use nuts and bolts to get a tighter fit. I have no idea what sizes I need and then how to put them in...  I am suffering from "mommy brain" I think! My bear making has been a mess and slow going lately and I hate it! Help me figure this out, please!!!!!

I am suffering from "mommy brain" I think! My bear making has been a mess and slow going lately and I hate it! Help me figure this out, please!!!!!

Hi Alexis,

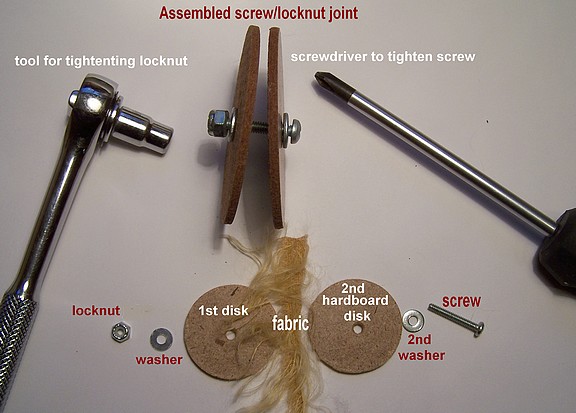

I took this picture showing how use the screw & locknut joints. Use the same size disc as you would with cotterpins. You might find it easiest to order a few joint sets to get an idea of the size hardware to use. For an 8" bear I would use a 1/2-3/4" long screw (that works well for thick fabric like real fur that I use mostly. I tighten really tight as it always loosens a bit when I stuff the bear.

WOW Tammy!!! That's an awesome photo!

I do it a little differently (don't we all!) in that I use epoxy glue to glue the head of the bolt to the washer and disc. This way I don't need the screwdriver to hold the head in place so it doesn't turn. I tend to use the 1/8" in diameter bolts. If you buy them at the hardware store that's the 6/32 size.... but I normally get them from my teddy supplier.

Hugz,

Laura

Great point Laura, I glue the head joint too ! I forgot to mention that.

Hey Alexis<

I usually order my joints in sets that already have the disks, washers nuts and bolts so I'm not too sure about the sizes but I can say that I glue all of my washers to each disk and all of the bolts to the 5 disks that are going into the head and legs and arms. This saves an awful lot of figiting and frustration with the screwdriver, then you can place the joint in the arm/leg, stuff it and sew it up then joint it into the body. I also find it easier to get a good clean ladderstitch to close the seam because I can work on the arm or leg without having to manuver the body and other limbs to get at the seam. Does that make any sence at all? I'm a bit sleepy today.

For the glue I have had great luck with Krazy glue gel, it's in a green tube with a red lid. I have also tried the new stuff that doesn't bond for 45 seconds, so you don't glue things to yourself but this has never worked well, the bolts always cam loose as I was jointing to the body and I had to un-stuff, joint and re-stuff all over again, and I just hate doing things twice!

Hope this helps a little!

Hugs,

AndreaM

Thanks soo much everyone! That picture is fantastic. I am so visual and I needed that to help me get it right! Thank you so much!

I use set screws so I am not wasting time gluing my discs to the bolt or having to smell the awful fumes. Set screws got together just like the nuts and bolts but there is a hole in one end of the screw that you put an allen key into to prevent it from turning. The nice thing about the set screws is that you can sew the arms and legs closed before jointing them to the body just like cotter pin joints.

Donna

Donna, I have two sets of set screws sitting here waiting to be used for several years. And you bet, the instructions have gone missing. I would love to use them. Could you explain how they actually work please?

It would be very muchly appreciated. :hug: :dance:

WEndy

Wendy,

Have you used nuts and bolts for jointing or just cotter pins? The set screws are very much like using nuts and bolts. Get out you sets and have a look. Each of the screws will have one end that has a hole in it and one end that is flat or closed. You will put your first lock nut on the end that is closed or flat. Your lock nuts will have a nylon insert inside the nut, you will want the end of the screw to extend slightly past the nylon. If you do not get the screw past the nylon it will come off after you have the critter made. Begin twisting the lock nut on the screw by hand, once you have it on the screw you will insert the allen key in the hole of the other end of the screw. By holding the allen key in the hole of the screw it will not allow the screw to turn. Then use a wrench or pliers to tighten down the nut onto the screw so that the screw is slightly past the nylon in the lock nut. You now are ready to put the washer and disc on the set screw and put it through the arm or leg. Sew your arm or leg closed. Now put your set screw with the arm attached through the body of the critter. Put your disc and washer on. Put the other lock nut on the screw and tighten down as much as you can with your hands. Put the allen key back in the hole in the end of the screw and hold it so the screw does not turn while you tighten down the nut with a wrench or pliers. I like to put a wrench on the nut and I have a bit that goes in my ratcheting screwdriver that fits in the end of the screw and then I hold the nut so it does not move and I tighten it down with my screwdriver. Let me know if you need pictures.

Donna

Thanks Donna. Sorry it took me so long to get back here. I put them together as you said. No problem there.

These are suppose to be easier and less fiddly is that right? Because for the life of me I cant figure out how.

I put the allen key in the end that will be in the body and have the spanner around the locknut... but I cant see how I can manipulate both at the same time? All that seems to be happening is the end that will be in the limb...the lock nut is travelling down further on the bolt thread. :doh: :doh: Sometimes I can be soooo slow..sheeesh....

hahahahahahahahah

Wendy

Wendy,

Most people have trouble with them right at first so don't get discouraged. Once you have it figured out, it will be a breeze to do these joints. When they were first introduced to me, for the life of me, I could not figure out how they would not be turning in the limbs. I finally gave in and gave them a try and am so glad I did. They are easier on your hands and wrists than cotter pin joints. And they give you a more consistent joint for tightness.

Now, for the locknut moving down the screw that is in the limb (the one acting as the bolt head), it can not move unless you have the wrench or spanner on it. Once you have the first locknut in place with the tip of the screw past the nylon in the locknut it will not move as long as you do not put a wrench or spanner on it. If it had been inside a limb, you would not have seen it or been able to get to it. Was that part of your problem? I hold the wrench with one hand that also is holding the discs, then with the other hand I turn the allen key. That way I feel the dics coming together as I tighten down the bolt. I'll try to get some pictures taken for you. That will force me to work on a bear, this is good!

Donna

Hi guys, I use nuts and bolts too, but instead of gluing OR fussing with slot head bolts, I use hex head bolts and stop nuts. I secure them using 2 nut drivers, one with a rachet end and one plain holding driver no screw driver needed. It is FAST, easy, no slipping or killing my hand with the screw driver. You get just as used to how tight to go using the 2 drivers as with the screw driver. I get all the nuts and bolts from my Ace hardware store. I buy in bulk boxes of 100 and save time, money and shipping. I often use 1/4" bolts for the larger bears -- that REALLY gives a secure joint.

Hope that was helpful,

Martha Burch (DeRaimo)

Let me see if I'm understanding this correctly: the measurements given have been for the width of the treaded portion. What are you all doing about the length?

And understand that I've never designed or sewn a bear that was larger than 4 or 5" so I've never hads the need to use these different systems, but I just want to know how you all do this: my question concerns the bolt length.

Do you purchase bolts that are the exact length that you need to go through 2 pcs of fabric, 2 washers, 2 disks and the ending bolt

Is there extra length that goes beyond the ending nut that just extends into the body?

Do you cut off this extra?